Functionality of Electric Valves

Functionality of Electric Valves

Understanding Skid-Mounted Equipment Efficiency in Modern Operations

Looking to the future, the role of regulators is poised for evolution. With advancements in technology, artificial intelligence and machine learning could play a role in enhancing regulatory processes. For instance, regulators may utilize data analytics to better monitor industries, identify risks earlier, and ensure compliance more efficiently. However, the integration of technology in regulatory practices must be managed carefully, with attention to privacy and ethical considerations.

Moreover, pressure reducing devices extend the lifespan of equipment. Consistent pressure levels minimize wear and tear on machinery, reducing maintenance costs and downtime. This reliability is particularly important in industrial applications where production continuity is critical.

1. Direct-acting Pressure Reducing Valves These are the simplest form, where the diaphragm directly controls the flow based on the detected pressure.

- Healthcare In the medical field, measuring gases such as oxygen and carbon dioxide in respiratory devices is pivotal for patient care, especially in critical care settings.

Natural Gas Filters The Key to Cleaner Energy Production

Disadvantages of Electric Heaters

In conclusion, shut-off valves are indispensable components that enhance the safety and efficiency of fluid handling systems. By understanding their function, types, and applications, industries and homeowners can make informed decisions about the appropriate valves needed for their specific requirements. Whether it is for controlling water flow in a household or managing complex industrial processes, shut-off valves play a critical role in ensuring reliable and safe operations.

- Water Supply In municipal water systems, PRVs help maintain consistent water pressure, preventing pipe bursts and ensuring adequate flow rates for consumers.

Natural gas is an essential energy source that powers homes, industries, and transportation across the globe. However, the journey of natural gas from the wellhead to the end-user involves an intricate network of pipelines and various components designed to ensure safety and efficiency. Among these components, the natural gas regulator plays a crucial role in the safe and efficient delivery of gas.

Relief valves come in several types, each suited for specific applications. The most common types include

Importance of Gas Pressure Reduction Valves

The development of supercharging began with pioneers like Tesla, which launched its Supercharger network in 2012. Designed to support long-distance travel, Tesla’s Superchargers provide high voltage direct current (DC) charging, significantly reducing the time it takes to recharge a battery compared to traditional alternating current (AC) chargers. Consequently, Tesla’s Supercharger network has become one of the largest and most recognizable in the world, featuring thousands of stations across multiple continents.

In the world of natural gas production and processing, the significance of a natural gas filter separator cannot be overstated. As one of the key components in the gas processing system, a filter separator plays a critical role in ensuring the quality and safety of natural gas before it enters the distribution network. This article delves into the functions, types, and importance of filter separators in natural gas applications.

In recent years, advancements in technology have led to the development of more sophisticated pneumatic control valves that incorporate smart systems and IoT capabilities. This evolution allows for better monitoring and control, further enhancing the capabilities of pneumatic systems.

What are Distribution Stations?

2. Manual Valves As the name suggests, these valves are operated manually using levers or knobs. They are often used in applications where automated control is not necessary.

Applications of Pressure Regulating Valves

In conclusion, relief valves are critical components in industrial systems that help protect equipment, personnel, and the environment from the dangers of overpressurization. By promptly releasing excess pressure, these valves prevent catastrophic failures and ensure the safe operation of various processes. It is essential for all industries to understand the importance of relief valves and to implement proper maintenance practices to safeguard their systems effectively.

In many countries, stringent regulations govern the installation and maintenance of gas safety valves. Compliance with these regulations is vital for ensuring public safety. Regulatory bodies require regular inspections and testing of safety devices to confirm their operational functionality. Failure to adhere to these standards can lead to legal consequences and, more importantly, pose serious safety risks to individuals and communities.

The Concept of المثبت (Al-Muthbit)

In various engineering and industrial applications, controlling the flow of liquids and gases is paramount for efficiency, safety, and operational integrity. Among the crucial components that facilitate this control is the closing valve, a device designed to regulate or halt the flow within a piping system. This article delves into the significance, types, applications, and working principles of closing valves.

Gas pressure reduction stations are typically located along natural gas pipelines at strategic points where the pressure of the gas needs to be reduced. These stations contain specialized equipment, including regulators, valves, and control systems, to carefully control the pressure of the gas as it flows through the pipeline.

2. Two-Stage Regulators As the name suggests, these regulators reduce pressure in two stages. They first lower the high inlet pressure to an intermediate level before further reducing it to the desired outlet pressure. This design offers greater stability and consistency in applications where pressure fluctuations could significantly impact performance, such as in industrial processes.

Overview of Gas Pressure Reducing Stations

In the ongoing pursuit of sustainable energy solutions, gasification has emerged as a significant technological advancement. A gasifier is a device that converts organic or fossil-based materials into carbon monoxide, hydrogen, and carbon dioxide through a process known as gasification. This process occurs in a low-oxygen environment, enabling the transformation of materials such as biomass, coal, or waste into syngas (synthesis gas), which can be used for various applications, including electricity generation, heating, and as a feedstock for producing chemicals and fuels.

In the modern industrial landscape, the management and filtration of gases have become critically important. Gas emissions are a significant environmental concern, and industries must address these challenges to adhere to regulations and ensure safety. One of the most effective solutions is the use of gas filters, which play a vital role in purifying air and other gas streams, thereby protecting both human health and the environment.

Operational Principles

1. Relief Valves These are designed to open and relieve pressure when it exceeds a set limit, allowing gas to escape safely. Once normal pressure is restored, the valve closes automatically.

2. Manual Shut-off Valves These valves require manual intervention to close off the gas supply. They are often installed in strategic locations for emergency shut-off.

While gasification technology displays great potential, several challenges remain. High capital costs associated with gasification equipment can be a barrier to entry for many municipalities and businesses. Additionally, the operational complexity and the need for skilled personnel to manage the systems can pose further difficulties.

2. Gasifier The gasifier is the core reactor where the actual gasification takes place. Various gasifier designs exist, including fixed-bed, fluidized-bed, and entrained-flow gasifiers. Each design has its advantages and is selected based on the type of feedstock, the desired end products, and operational conditions. In this unit, feedstock is subjected to high temperatures (usually between 700°C to 1500°C) in the presence of limited oxygen, triggering thermochemical reactions that convert it into syngas.

A gas pressure regulator valve is a mechanical device that reduces and controls the pressure of gas coming from a source, such as a gas main or tank, before it reaches its intended application. The primary function of the regulator is to maintain a steady output pressure, regardless of fluctuations in the input pressure or the demands of the downstream equipment or systems.

Conclusion

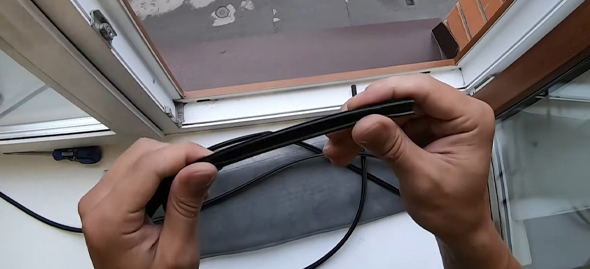

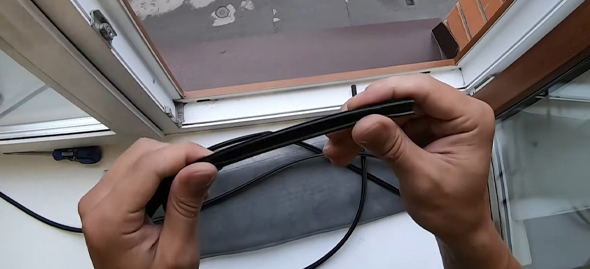

Weather stripping is a material used to seal the movable parts of windows and doors to prevent air leaks. Thin rubber weather stripping is particularly popular due to its versatility and effectiveness. Made from durable rubber, this type of weather stripping can conform to the uneven surfaces often found around doors and windows, ensuring a tight seal. Unlike thicker materials, thin rubber weather stripping occupies less space, making it suitable for various applications without hindering the functionality of the door or window.

2. Enhanced Comfort Properly sealed windows help maintain a consistent indoor temperature, enhancing the overall comfort of your home. You won’t have to deal with cold drafts in winter or warm spots in summer, making it easier to enjoy your living spaces throughout the year.

Functions of Window Strip Seals

Electronics manufacturing also heavily depends on effective edge sealing. The introduction of moisture and dust can significantly hinder the performance of electronic devices. For instance, sealing edges on circuit boards helps prevent corrosion, ensuring a longer lifespan and reliability of electronic products such as smartphones, laptops, and home appliances. Techniques like conformal coating, which involves applying a protective polymer layer over electronic components, serve as vital sealing methods that provide a barrier against environmental hazards.

Booster pump mechanical seals are fundamental to the efficient and reliable operation of pumping systems. Understanding their design, functionality, different types, and the importance of maintenance can significantly enhance operational performance and prevent costly downtime. By investing in quality seals and adhering to rigorous maintenance protocols, industries can ensure that their booster pumps operate at peak efficiency, delivering reliable service for years to come.

- Industrial Equipment Many manufacturers use EPDM strips to seal machines and equipment against dust and moisture, enhancing their operational efficiency and longevity.

A car soundproof weather strip is a special type of insulation material that is designed to reduce the amount of noise that enters the cabin of your vehicle. It is typically made of materials like rubber or foam, which help to absorb sound waves and prevent them from penetrating into the interior of the car.

An exterior door weather seal is a type of sealing material that is installed around the perimeter of exterior doors. Its primary function is to close gaps between the door and its frame, preventing air leaks, moisture infiltration, and dirt or pest entry. Weather seals can be made from various materials, including rubber, foam, vinyl, and silicone. Each material has its advantages and disadvantages, making it essential to choose one that fits your specific needs.

4. Cut to Size Most weather stripping can be easily cut to the desired length using scissors or a utility knife.

2. Cleaning Keep the seals clean by wiping them down with a damp cloth and mild soap. This helps remove dirt and debris that can degrade the material over time.

2. Inspection Regularly inspect the trim seals for cracks, tears, or any signs of wear. Promptly replacing damaged seals can prevent more significant issues down the line.

Understanding Weather Seals

Secondly, their durability is a significant advantage. Rubber seal strips can withstand a wide range of temperatures and environmental conditions, ensuring that they maintain their sealing properties over time. This longevity translates to reduced maintenance costs and fewer replacements.

They can be customized to meet the specific requirements of different pump applications, such as varying temperatures, pressures, and fluid types They can be customized to meet the specific requirements of different pump applications, such as varying temperatures, pressures, and fluid types

They can be customized to meet the specific requirements of different pump applications, such as varying temperatures, pressures, and fluid types They can be customized to meet the specific requirements of different pump applications, such as varying temperatures, pressures, and fluid types mechanical seal for high pressure pump. This allows manufacturers to optimize their pump designs for maximum efficiency and performance.

mechanical seal for high pressure pump. This allows manufacturers to optimize their pump designs for maximum efficiency and performance.Benefits of Installing Bottom Door Seal Rubber

5. Easy Installation Most car door trim protectors are designed for simple installation processes. They often come with adhesive backing or clips that make it easy for anyone to attach them to their vehicle without the need for professional help. This convenience ensures that car owners can quickly enhance their vehicles’ protection without a significant time investment.

1. Cracks or Tears Inspect the weather stripping for visible signs of damage. Cracks or tears can compromise the seal.

While protection is the primary concern, truck door edge trim can also enhance the vehicle's aesthetic appeal. Available in a variety of colors, finishes, and styles, trim can provide a sleek, finished look to the doors, adding to the overall design of the truck. Whether you prefer a minimalist look or a bold accent, there is a door edge trim option that can complement your vehicle’s appearance.

- Electronics Many electronic devices use self-adhesive foam seals to protect sensitive components from dust and moisture. This application helps extend the lifespan of electronic equipment.

The material's ability to absorb shock and provide a non-slip surface makes it ideal for use in sports equipment and safety gear The material's ability to absorb shock and provide a non-slip surface makes it ideal for use in sports equipment and safety gear

The material's ability to absorb shock and provide a non-slip surface makes it ideal for use in sports equipment and safety gear The material's ability to absorb shock and provide a non-slip surface makes it ideal for use in sports equipment and safety gear flocking rubber. Moreover, the vibrant colors and patterns available allow for endless customization options, making each piece truly one-of-a-kind.

flocking rubber. Moreover, the vibrant colors and patterns available allow for endless customization options, making each piece truly one-of-a-kind.Flexible Rubber Edge Trim A Versatile Solution for Protection and Aesthetics

2. Environmentally Friendly EPDM is considered an environmentally friendly option as it does not degrade easily and can be recycled. Many manufacturers also produce EPDM from sustainable sources, aligning with green building practices.

What is Weather Stripping?

The Importance of Weather Door Seal Strips

In the world of adhesive solutions, few products can boast the versatility and effectiveness of foam tape. Among these, the 3-inch wide foam tape stands out due to its numerous applications and benefits, making it an indispensable item for both professionals and DIY enthusiasts alike.

In today's world, where energy efficiency and environmental sustainability are key concerns, the demand for effective sealing solutions has never been greater. One such solution that has gained popularity is foam sealing tape, particularly for its waterproof properties. This versatile material is commonly used in various applications, from construction and automotive industries to everyday household repairs. Understanding the benefits and applications of foam sealing tape can greatly enhance its utility and effectiveness.

Importance of External Weather Stripping

5) Check whether the products have cutting defects;

1. Energy Efficiency One of the most important benefits of corner seals is their ability to enhance a home’s energy efficiency. Properly sealed doors help maintain temperature levels inside the house, reducing the load on heating and cooling systems. This not only keeps your home comfortable throughout the year but also translates to lower energy bills.

2. Comfort Drafty doors can lead to uncomfortable temperature fluctuations inside your home. By sealing these gaps, you can ensure a more stable indoor climate, making it easier to enjoy your living space throughout the year. No one wants to be in a room where chilly drafts disrupt relaxation or productivity.

- Versatile Applications Whether you are working on a home renovation, crafting a project, or repairing equipment, the 1mm self-adhesive rubber strip can be applied in a multitude of ways, enhancing its overall value.

One of the primary functions of rubber strips in cars is to provide protection against the elements. They are designed to seal gaps between various car parts, preventing moisture, dust, dirt, and debris from entering the vehicle. This sealing capability is particularly vital for windows, doors, and sunroofs. By using rubber strips, manufacturers ensure that vehicles remain free from water leaks that can cause mold growth or rust in the body. Moreover, these strips act as insulators, keeping the interior climate controlled by reducing drafts and ensuring that air conditioning systems operate efficiently.

Aesthetic Appeal

Another noteworthy application of thick foam strips is in the sporting goods sector. Athletes and fitness enthusiasts often require equipment that supports their performance while ensuring safety. Foam strips are commonly integrated into protective gear such as knee pads, elbow pads, and helmets, providing vital cushioning that absorbs impact and reduces the risk of injury. Additionally, thick foam strips are used in gym flooring systems where they act as shock absorbers, making workouts safer and more enjoyable.

Advantages of Waterproof Foam Seals

4. Marine Applications Given its resistance to moisture and saltwater, EPDM is widely used in marine environments. It finds applications in boat seals, gaskets, and various fittings, where it helps prevent water ingress and protects against corrosive elements typical of marine settings.